Products

Exhibition

Industry News

What’s the difference between hot and cold rolling mills?

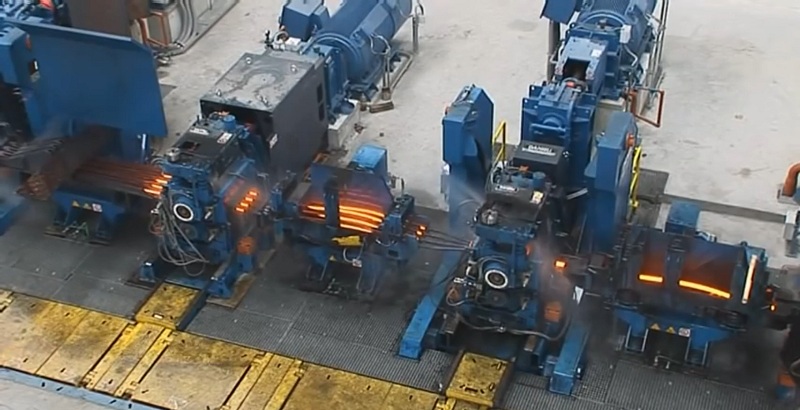

Author : hani Time : 2019/09/27In the hot rolling process, the slab is mainly made of continuous casting slab. After heating, the strip is made of cold rolling mill and hot rolling mill. The finished steel of hot rolling mill is cooled to laminar flow to establish temperature band. It is coiled in the coil by winding machine, and coil cooling is a finishing operation according to different needs. Users straighten the cross-section of leveling line. The inspection of surface and longitudinal section and the treatment of packaging turntable become flat steel rolls and longitudinal cutting steel.

In short, the workpiece is heated, the red and hot steel pieces burned on the equipment machine have been rolled many times, then cut and cut into a steel plate. The cold rolled coil is used as raw material. After stripping off the oxide skin, the cold rolled coil is used for cold treatment, and the finished product is coiled into the hard coil, which is caused by cold hardening caused by continuous cold deformation. Hardness, toughness index, increase and decrease – low of hard roll, so stamping performance will deteriorate and can be used for simple deformed debris, cold rolled hard roll can be used as the raw material of hot dip galvanizing equipment because hot dip galvanizing unit has annealing line.

Usually, the weight of rolls is about 10 tons, and the coil is coiled continuously to the normal temperature of hot-rolled pickling rolls because it has no annealing, high hardness, and poor machinability. It can only perform simple directional push-ups less than 90 degrees. For simplicity, the number of cold rolling techniques is processed and based on hot-rolled coils, taking into account the rolls. The dynamic change of vibration displacement in the vertical direction of cold rolling and the dynamic model of rolling force is set up.

According to the calculation formula of rolling force, the formula for calculating rolling force is derived from the decoupling of rolling force and rolling radius of flat state. On this basis, the influence of mechanical structure vibration of cold rolling mill is further considered, and the equation of non-linear vertical vibration system with a rolling force of dynamic rolling mill is established. The main equation of the system’s equilibrium frequency is solved by wave balance method, and the actual parameters are simulated to analyze the non-linear stiffness.