Products

Exhibition

Industry News

What Is the Ladle Refining Furnace?

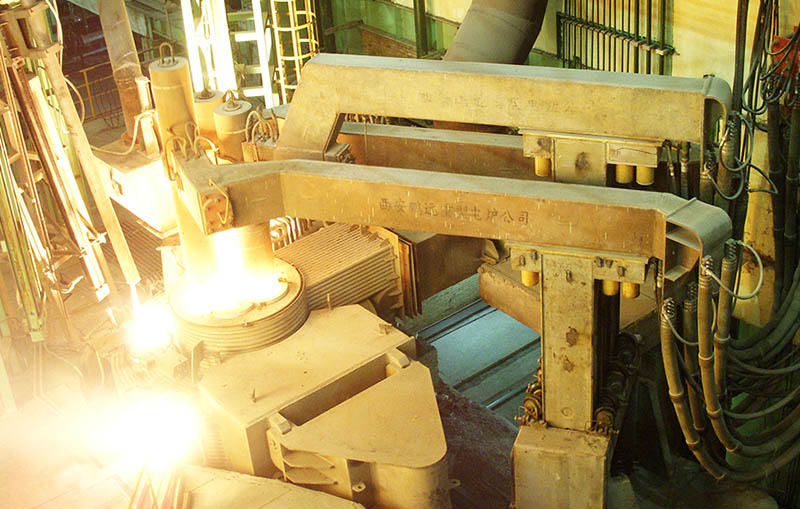

Author : hani Time : 2020/08/05Ladle refining furnace is important metallurgical equipment for refining molten steel from primary refining furnace (electric arc furnace, open-hearth furnace, and converter), and can adjust the temperature of molten steel, process buffer, and meet the requirements of continuous casting and continuous rolling. A ladle furnace is one of the main equipment in secondary refining.

The main functions of the ladle refining furnace are as follows:

1. Heat up and heat preservation of molten steel. The new heat energy can be obtained by arc heating, which can not only add alloy and adjust composition but also add slag to facilitate deep desulfurization and deoxidization of molten steel. Moreover, the starting temperature of molten steel required for continuous casting is guaranteed, which is beneficial to the improvement of the quality of the dry casting billet.

2. Argon stirring function. Argon is blown into the molten steel through the permeable brick installed at the bottom of the ladle, and the molten steel obtains a certain stirring function.

3. Vacuum degassing function. After the ladle is hoisted into the vacuum tank, the steam jet pump is used for vacuum degassing. At the same time, argon is blown into the ladle bottom to stir the molten steel. The hydrogen content and nitrogen content in the molten steel can be removed, and the oxygen content and sulfur content can be further reduced. Finally, steel with higher purity and superior material properties can be obtained. The application of ladle refining furnace can increase the following benefits for the whole enterprise: speeding up the production rhythm and improving the metallurgical production efficiency. The application of ladle refining furnace covers industry, steel, metallurgy and other industries.

Operating procedures:

1. Before working, check whether the interlock protection device and travel switch of the ladle car are safe and reliable.

2. Check the vacuum system, oxygen blowing, hydrogen blowing, heat preservation, heating, feeding, and other mechanical parts, and start the operation only after confirming that they are safe and reliable.

3. Check whether the sample spoon and mold are kept dry.

4. Check whether the working position apparatus is easy to use.

5. Contact with power supply unit and vacuum control room according to regulations.

6. Ring the bell or turn on other safety signals before driving.

7. Carry out high voltage power transmission and vacuum degassing according to the procedure.

8. When starting the ladle car, the track must be checked and obstacles must be removed at any time.

9. It is forbidden to pass under the high voltage line after power transmission.

10. When connecting and unloading the pressure pipe joint, the valve must be closed before operation.

11. When using oxygen, it is strictly forbidden to hold hands in front of the card head and wear greasy gloves.

12. After sampling, the remaining molten steel should be poured into the dry place.

13. When the vacuum is removed, all personnel are not allowed to approach the air supply pipe orifice.

14. For inspection and maintenance, when it is necessary to mount the heating bridge for operation, the high-voltage key must be pulled out, the high-voltage power supply must be cut off, and the operator should bring the key himself.

15. When lifting and changing electrodes, special personnel shall be assigned to command. The lifting ring and the hook should be connected with steel wire rope, and the hook insurance should be closed. It is forbidden to open three phases at the same time for hanging and changing.

16. Objects shall not be stacked on the furnace cover and bridge, and it is forbidden to throw objects up and down when working on the bridge.