Products

Exhibition

Industry News

What Are the Advantages of Slitting Rolling?

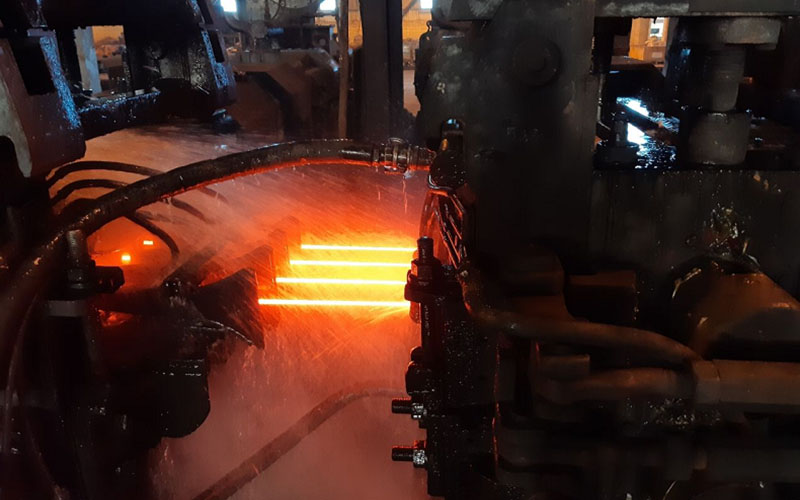

Author : hani Time : 2021/10/25Slitting rolling is a new technology widely studied and applied at home and abroad in recent 20 years. The so-called slitting rolling is the rolling process in which the billet is rolled into two or more parallel parts with the same section shape through the pass design, and then the billet is cut into two or more rolled parts with the same section shape longitudinally by the slitting equipment, and rolled continuously until the finished product is obtained.

According to the different structural characteristics of the segmentation equipment, there are currently several different segmentation methods as follows:

1) Roll cutting method

Use the mill roll to split the pass. The rolled piece is cut while deforming in the pass;

2) Split rounds

First, roll the rolled piece into two or more parallel pieces of the same shape through the pass, and then cut the rolled piece by the slitting wheel installed on the exit side of the rolling mill;

3) Disc shear method

First, the rolled piece is rolled into a shape to be divided, and then the rolled piece is cut longitudinally by a disc cutter installed on the rolling line.

In addition to the above-mentioned cutting methods, flame-cutting is also used.

Compared with the traditional single-root rolling process, split rolling has many advantages, mainly:

1) Reduce the number of racks and save workshop investment.

Under the condition that the blank and product specifications are the same, the rolling passes of slitting rolling technology are less than those of ordinary single rolling passes (for example, when 130mm square billet is used to produce 12mm diameter reinforcement, the rolling passes can be reduced from 16 passes of single rolling to 14 passes of slitting rolling), which creates conditions for reducing the number of racks, shortening the plant length and saving the workshop investment.

2) The rolling rhythm can be shortened, and the output of the rolling mill can be greatly increased.

For example, when a foreign factory produces steel bars (rolling speed is 14m/s), the output of single-strand rolling is 22t/h, and after rolling with double strip cutting equipment, the output of the rolling mill is increased to more than 40t/h. Another example is a set of 130mm billet produced by another foreign factory to produce 16mm round steel. The original process finish rolling speed is 12m/s, and the output is 60t/h. After split rolling, the finish rolling speed is only 7.3m/ s, the output of rolling round steel of the same specification can reach more than 60t/h.

3) The small rolling mill can open the big billet, which provides sufficient room for the selection of the billet of the rolling mill, and is beneficial to solve the problem of connection and matching between the rolling mill and the continuous casting billet.

For example, a 68mm square billet was used in a mill to make a wire rod with a diameter of 6.5mm through 21 passes. After adopting slitting rolling technology, wire rod with the same specification with performance meeting the requirements were rolled with a 90mm square billet.

4) It can reduce the production cost more.

According to statistics, the use of split rolling technology on section steel mills, wire rod mills and tube billet mills can reduce rolling power consumption by 15-30%; billet heating fuel consumption can be reduced by 1.8%-2%; roll consumption can also be reduced quantity; the cost of rolled material can be reduced by 10-20%.