Products

Exhibition

Company News

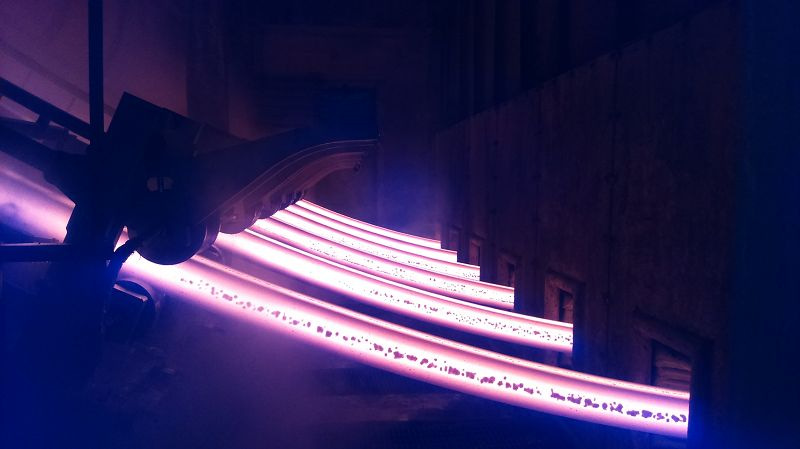

Continuous Casting Technology Characteristics of the Horizontal Continuous Casting Machines

Author : hani Time : 2019/11/01The continuous casting technology of horizontal continuous casting machines can be developed rapidly because it has many advantages over traditional casting techniques. Compared with die casting, the larger feature of continuous casting is the elimination of the mold release, the entire mold, the ingot heat, and the blanking process. Capital investment can save 40%, reduce floor space by 30%, save labor by 75%, shorten product production cycle and improve production efficiency.

The cutting loss of the cutting head of the horizontal continuous casting machine is 10%~20%, and the tail cutting loss of the continuous casting is only 1%~2%, so the metal yield can be increased, the waste of raw materials can be reduced, and the waste can be reduced. Cost; and continuous casting eliminates the reheating process of the soaking furnace, which can reduce energy consumption by 1/4~1/2. The direct casting of the slab can further reduce energy consumption and shorten the processing cycle.

The foundry workshop has a harsh working environment and many manual labors, which is a relatively backward process in the entire production line. After the special-shaped copper rod is continuously cast by a horizontal continuous casting machine, the labor environment has been fundamentally improved and easily automated due to the improvement of equipment and operation level and the use of full-time computer control and management.

The continuous casting process of the horizontal continuous casting machine can produce a variety of metals and alloys, and the variety of profiles is large. Since the metal is rapidly cooled, the crystal is dense and the structure is uniform, and a good quality casting blank can be obtained. In addition, the continuous casting technology of horizontal continuous casting machines can be divided into different types to meet different casting requirements.

According to the direction of the mold, the continuous casting is divided into horizontal continuous casting and vertical continuous casting. According to the continuous casting machine, it can be divided into vertical continuous casting machine, vertical bending continuous casting machine and vertical multi-point bending type. Continuous casting machine, arc continuous casting machine and horizontal continuous casting machine; etc.; according to the shape of the casting blank can be divided into slab continuous casting machine, billet continuous casting machine and round billet continuous casting machine.