Products

Exhibition

Industry News

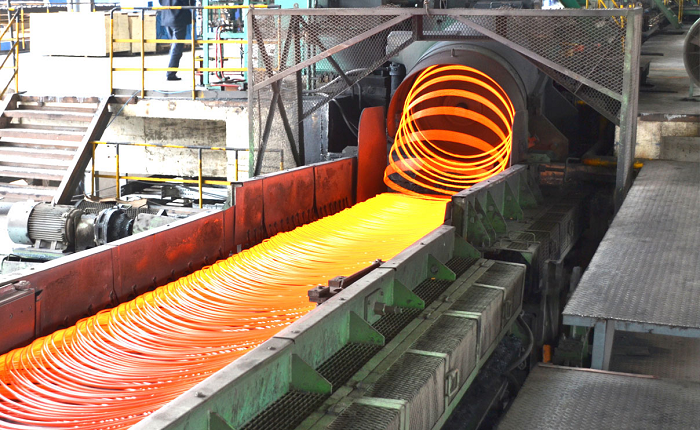

Causes and Solutions of Steel Piling-up in Wire Rod Rolling Mills?

Author : hani Time : 2019/07/23Causes and solutions of steel piling-up in high-speed wire rod rolling mills?

The phenomenon of steel piling-up occurs during rough rolling and medium rolling of high-speed wire rod mills, which can be divided into steel heaping at the head, middle and tail of the rolled piece.

Specific reasons and solutions are as follows:

1. Steel piling-up on the head of the rolled piece.

1) The frictional force of the groove is too small after changing rolls and grooves, which causes the head of the rolled piece to slip.

2) After the head of the rolling piece is out of the frame, the head warping leads to the failure to successfully bite into the downstream frame or the head top guide position.

3) There are foreign bodies in the rolling groove or guide groove;

4) The billet is seriously out of square and cannot enter the high-speed wire rod rolling mills or take out the outlet pipe.

5) Slab splitter top guide or winding roll.

Terms of settlement:

1) Increase the friction force of groove when changing roll and groove, grind groove with grinding wheel or adopt spot welding method, and close the cooling water of roll until it is completely bitten in;

2) Check whether the rolling mill guide base is loose, whether the rolling line is aligned, and replace the old guide in time.

3) Cleaning iron oxide scale in time during the rolling process;

4) During the rolling process, the unqualified billet should be cleared in time and the splitter should be stopped as soon as possible to reduce the treatment time of scrap.

2. Steel piling-up in the middle and tail of the rolled piece

1) Steel heap due to improper roll gap setting;

2) Defects of billet, such as inclusions and bubbles, break during rolling and cause stacking of steel.

3) The speed of the high-speed wire rod rolling mills are designed improperly and in the state of stacking rolling. When the front half of the rolling piece is in front of the rolling machine to maintain micro-tension rolling, when the tail of the rolling piece leaves the front rolling mill, the tension suddenly loses at this place, which causes the stacking of the tail of the stand.

4) Steel heap is caused by a sudden increase or decrease of frame motor speed.

5) Steel heap is caused by sudden breakage of roll or serious damage of the previous guide.

Resolvent:

1) After changing rolls and grooves, the groove bottom should be set accurately, the diameter and speed of rolls should be measured correctly, and the speed error should be reduced.

2) Strengthen the inspection of unqualified billets;

3) Correctly adjust the tension between the racks;

4) Inspection of electrical equipment and replacement of damaged electrical components;

5) Check the amount of cooling water for rolls, adjust the steel temperature, and prohibit rolling low-temperature steel and black head steel.