Products

Exhibition

News

-

The Flying Shears of Steel Rolling Mill

1. Basic Requirements for Flying Shears The cutting edge is synchronized with the rolling piece in the direction of the rolling piece’s movement: V=(1-1.03) Vo, Vo is the rolling piece speed, and at the same time completes the cutting to length...

MORE -

Universal Joint Shaft Production Process

Universal Joint Shaft Production Process In the process of adjustment and treatment of universal joint shaft, it is generally the means to complete heat treatment under the condition of flame quenching at a higher temperature. If there is no special ...

MORE -

Common Defects and Treatment Methods on the Surface of Ba...

Product Quality Defect Common defects on the surface of bar and wire rod 1.1 Defects in raw materials 1.1.1 Shrinkage cavity—There are residual shrinkage cavities and the resulting defects in the steel. Reason: ① Shrinkage hole o...

MORE -

Comparison of Electric Furnace, AOD furnace, LF furnace a...

Electric Furnace The electric furnace steelmaking process mainly uses arc heat, and the temperature is up to 4000 ℃ in the arc action zone. The smelting process is generally divided into the melting period, oxidation period, and reduction period. I...

MORE -

Industrial Frequency Induction Furnace

The industrial frequency induction furnace is an induction furnace with an industrial frequency current (50 or 60 Hz) as the power source. The industrial frequency induction furnace has been developed into smelting equipment with a wide range of uses. It is...

MORE -

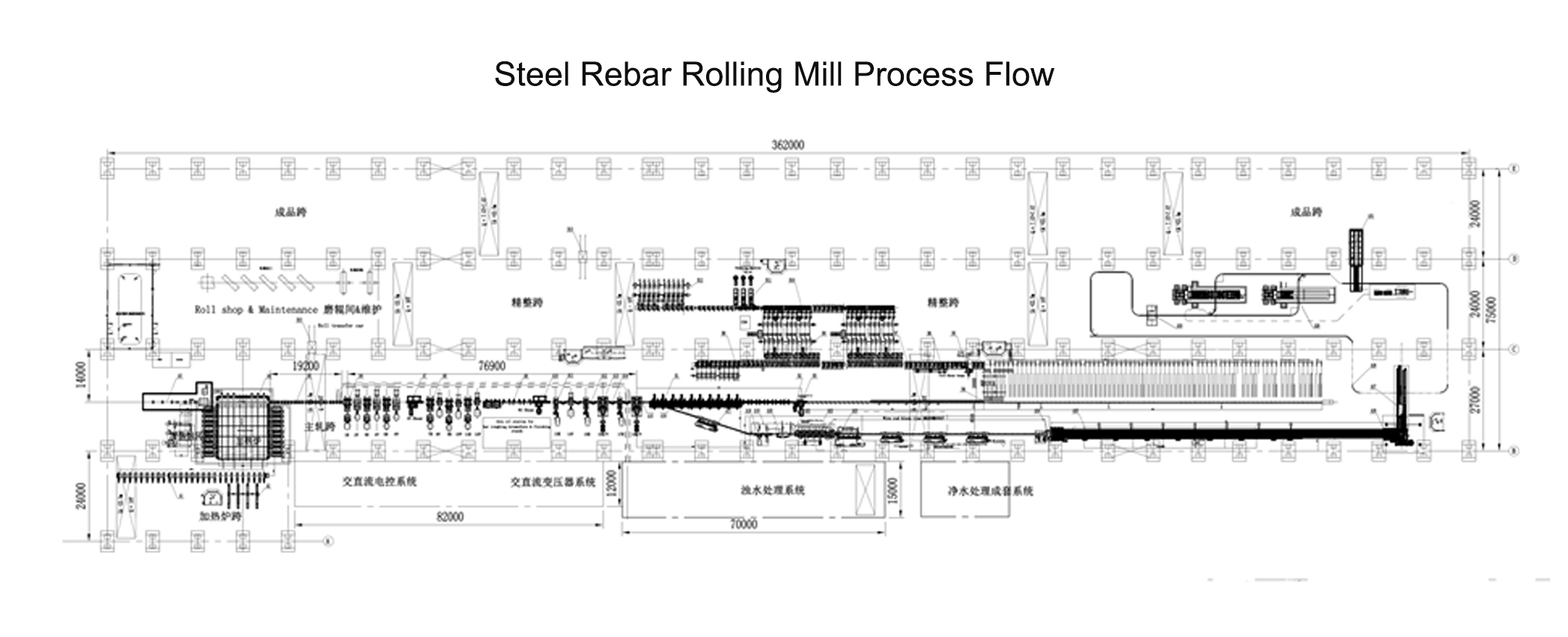

Steel Rebar Rolling Mill Process Flow

Steel Rebar Rolling Mill Process Flow The Steel Rebar Rolling Mill Process Flow is as follows: Steel billet acceptance → heating → rolling → double-length shearing → cooling → shearing → inspection → packaging → measurement → storage Billet Acceptanc...

MORE